What?

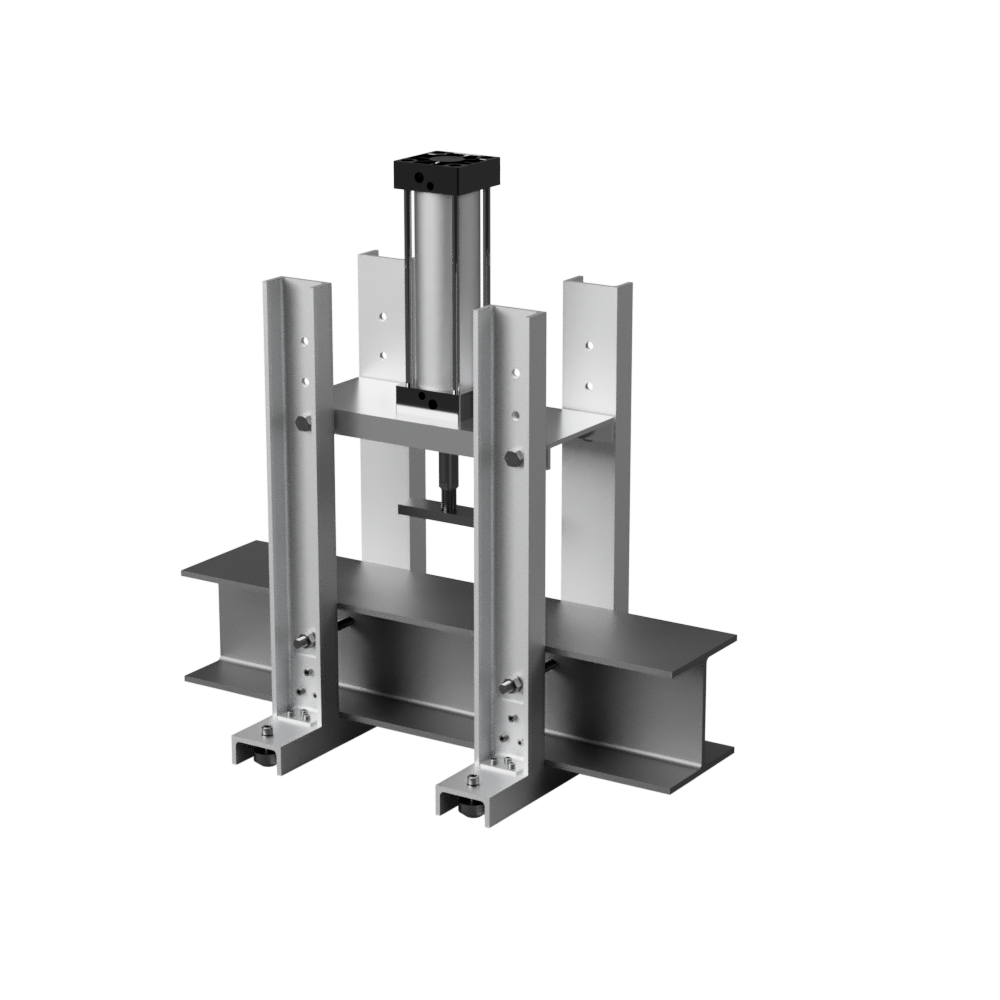

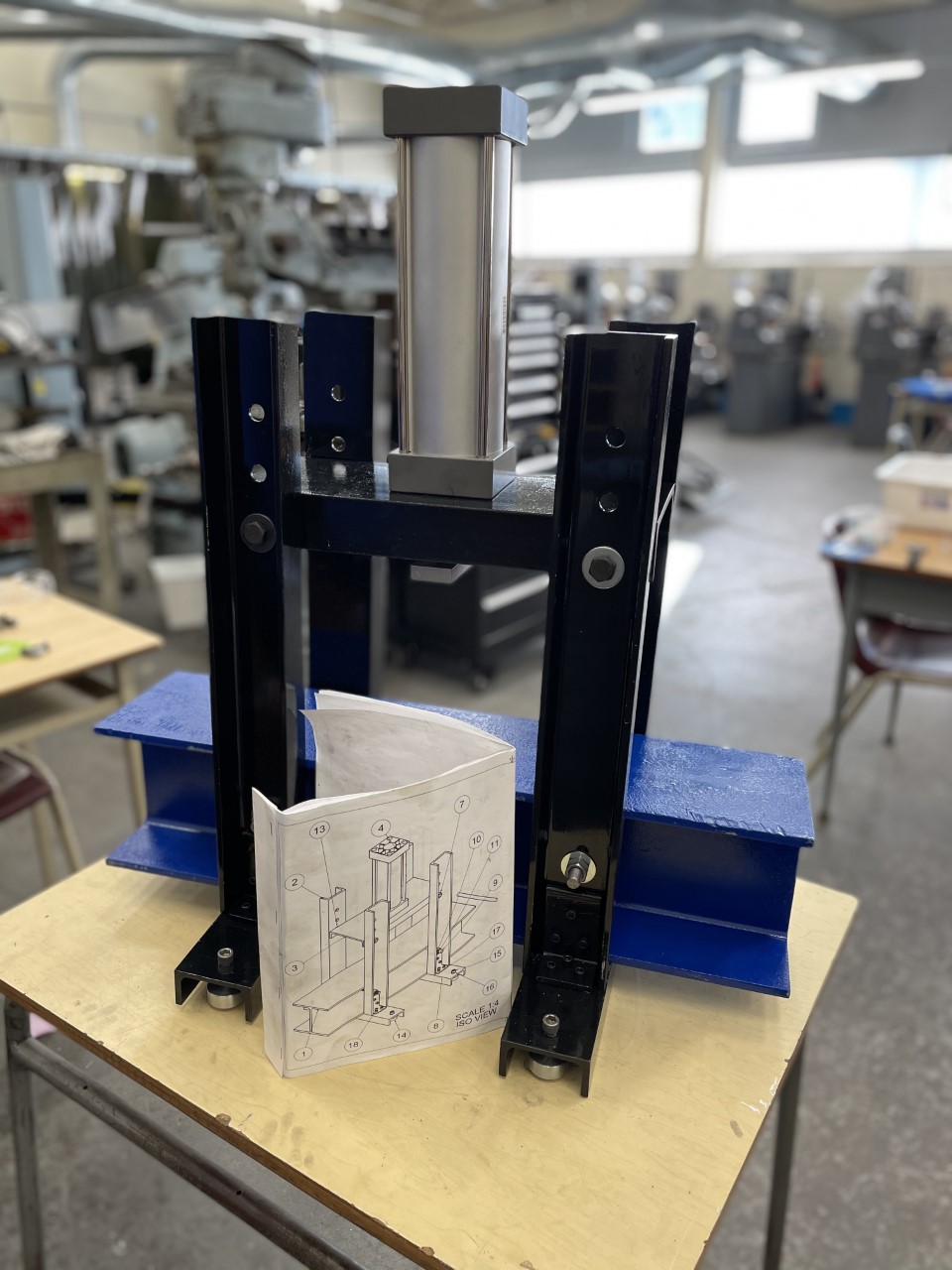

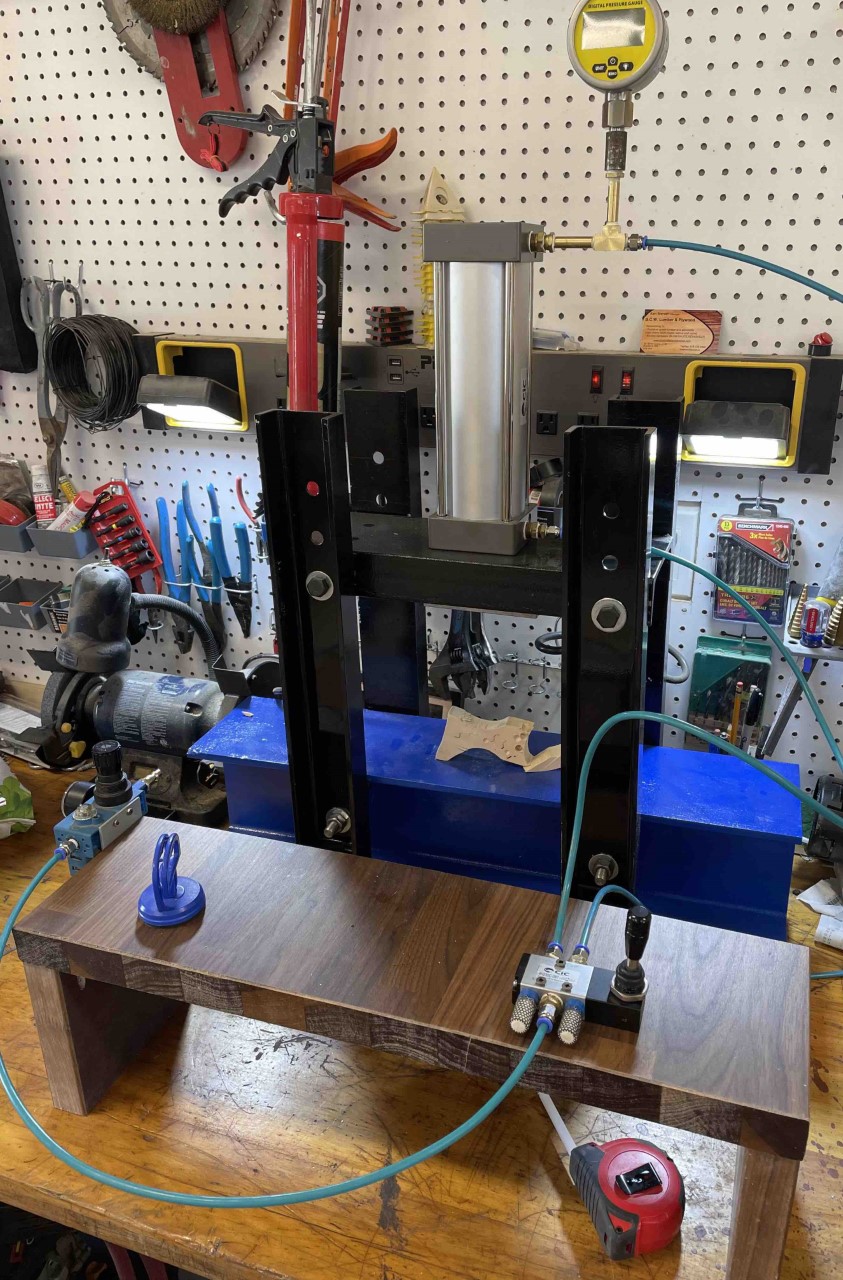

The Grade 9’s taking the “Exploring Tech” course had an upcoming competition, which was a popsicle bridge competition. Working with my tech teacher/mentor, I designed and created engineering drawings for a deflection tester, or, the bridge crusher, which consisted of a pneumatic tie-rod cylinder, I-Beam, and many other components.

Why?

As I was working with my tech teacher who knew I was getting into 3D-designing and leading the club, he wanted to prepare me for engineering at university and give me more challenges and opportunities to grow as an engineering student. Moreso, there was no suitable bridge crusher for the competition, so this raised another designing opportunity for me. Alas, we got to work.

Images

Challenges

One of the challenges was being the designer, and having to come up with logical decisions by yourself. Should I design it like this? That way? I was communicating with my tech teacher/mentor over email, and I couldn’t stuff every thought and question I had, so I had to take initiative and go with what I thought was the right or good decision for designing the deflection tester

After many iterations of doing the designing on Fusion 360, it was finally time for creating the drawings. After creating drawings for each separate component and the assembly itself, I had to get it reviewed by my mentor. After he had reviewed and sat down with me to go over it, all I saw was just red markings everywhere. There were a lot of improvements that the drawings could have, and I learned a lot about doing mechanical drawings after this.

Result

The competition was a success! They live-streamed it, and it was really cool to see something I designed working in front of my screen, and being actually used for a competition. The best part was seeing my creation destroying the popsicle bridges that the Grade 9’s worked hard for. Jokes aside, the best bridge was able to withstand over 500lb of force, which took first place by miles ahead!